There are many creative possibilities for print :

Varnishes

A varnish is a liquid shellac or plastic-like put on a printed piece like a layer or clear ink, varnish adds a glossy, satin or matte finish. Part of the printing or finishing process, varnish is applied like a final layer of ink after a piece is printed. It may be clear or tinted.

Glossy finish

Matte finish

Spot varnish

This is a special effect that puts an overprint varnish only on specific areas of a printed piece, spot varnish is often used to make a photograph pop off the page, highlights drop caps, or to create texture and subtle images on the page. The term spot varnish can refer to more than just clear ink or resin varnish but also to the spot application or Ultra-violet (UV) coatings or Aqueous (AQ) finishes.

Lamination

This is one of the more expensive but more accurate types of prepress proofs are laminate proofs. These full-color proofs are created from the negatives used to make the printing plates. Each separation is transferred to a separate sheet and the layers are fused or laminated together to give an extremely accurate representation of the final printed piece.

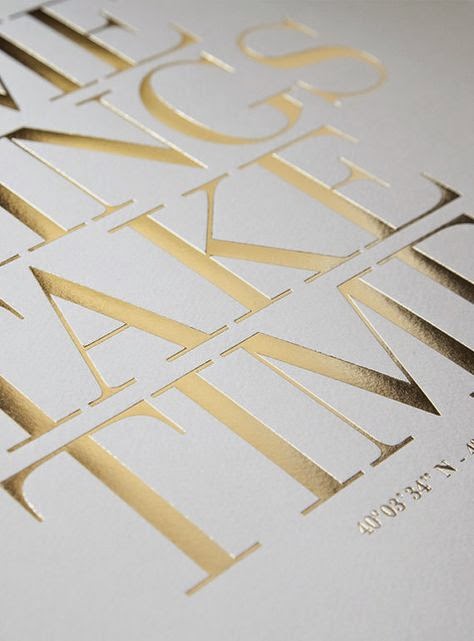

Foil Stamping

Foil stamping is the use of a malleable metallic material applied to the print surface by using heat and pressure. Foil stamping is the application of foil, a special film-backed material, to paper where a heated die is stamped onto the foil, making it adhere to the surface leaving the design of the die on the paper. Foil stamping can be combined with embossing to create a more striking 3D image.

Embossing

The creation of a raised three-dimensional design or image on paper is known as embossing. Heat and pressures reshapes the surface of the paper to create the image. Single, multi-level, beveled, and sculptured are the styles of embossing. Embossing can be done on plain paper (blind embossing) or combined with ink, images, or foil for special effects.

Embossing is a way to add visual and tactile interest to paper. It adds texture, value, (and color if using ink or foil embossing) and perhaps other elements of design depending on the type and placement of the embossing.

The entire surface of the paper can have an embossed finish. Logos, lines, and other images may be embossed on portions of the page. Embossing is done during the printing and finished stage of a design (or during the papermaking process). Embossing machines and individual embossing stamps are also popular in paper crafting and scrapbooking. The look of embossing can also be achieved using embossing powders or inks which can be applied to paper to create a raised design.

Debossing (or Letterpress) : it's the opposite of embossing. Traditionally, the letterpress technique was used only for applying ink on a page as a form of relief printing and usually only for text. But it has evolved to also include pressing logos and other design elements directly into the paper substrate.

Thermography

Thermography uses a special powder which is added to the document with it adhering to the ink printed on the paper. After removing the excess powder the printed piece is heated and the powder and ink mixture dries to form a raised effect on the paper.

Die Cutting

Die-cutting is a process used in many different industries to cut a thin flat material (in our case, paper) into a specific shape using a steel cutting die. It can be used to punch out a decorative shape or pattern to incorporate within a larger piece, or it can be used to create the main shape of an object by cutting the entire sheet of paper in an distinct/designed way. More simply put: for us it’s way of making a hole in paper in a desired shape using the same presses that we use for letterpress printing.

Laser Cutting

Laser cutting is a non-contact process which utilizes a laser to cut materials, resulting in high quality, dimensionally accurate cuts. The process works by directing the laser beam through a nozzle to the workpiece. A combination of heat and pressure creates the cutting action. The material melts, burns, vaporizes, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish.

Screen Printing

Screen printing (also known as silk screening) is one of the oldest methods of printmaking, with examples dating back to the Song Dynasty in China. The process involves creating a stencil of an image on a screen of porous mesh, traditionally made of silk. A roller or squeegee is used to pull paint-like ink over the stencil, forcing it through the mesh onto the paper being printed. Unlike the inks used in some other forms of printing, screen printing ink sits right on the surface of paper, resulting in incredibly rich, vibrant color.